Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

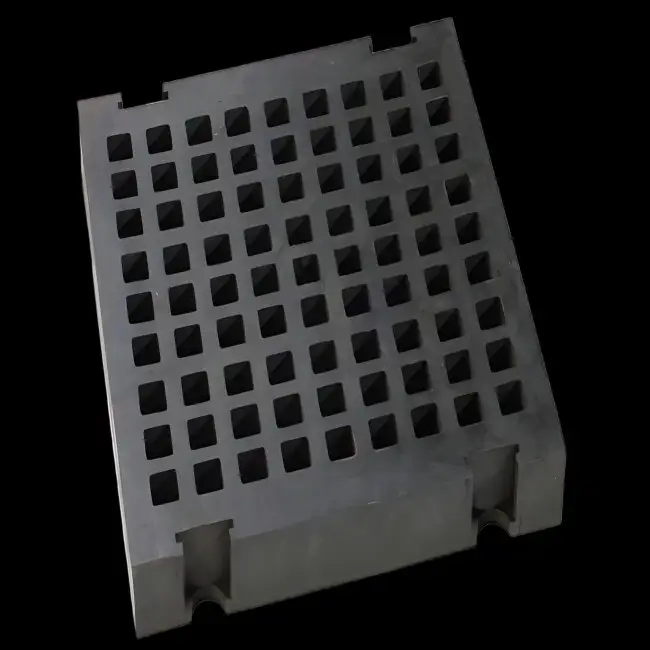

120mm Square Aperture Rubber Screen Panel 305×610mm for Coarse Mining Applications

Screening situation: Coarse,medium,fine,and semi-automatic mill discharge

Package: Carton Box or Wooden Box

Payment Terms: T/T, Paypal.

Shipping Options: FedEx, DHL, UPS, Air Freight, Sea Freight, Train, Truck

Terms: EXW, FOB, CIF, DDU, DDP

Rubber Screen Panels

Product Information

HUATAO’s rubber screen panels are tailored for mining’s toughest challenges, from abrasive ore processing to high-moisture dewatering. Their compression-molded construction ensures uniform quality, with apertures ranging from 0.3×12mm to 120mm to handle particles 0.1–100mm. The rubber’s Shore hardness (32–90) is optimized to resist pegging: softer compounds for fine materials, harder ones for coarse rocks. Steel reinforcement adds strength, allowing them to absorb impacts from large ore chunks without tearing. Suitable for both vibrating screens and trommels, they work in dry conditions (coal scalping) and wet environments (slurry dewatering). Customizable options—including high-temperature rubber and oval holes—meet specific operational needs, while easy installation minimizes downtime. By reducing noise and maintenance, these panels create safer, more efficient mining workflows.

Product Advantages

In mining, where efficiency and durability are paramount, HUATAO’s rubber screen panels deliver on both fronts. Their unique blend of rubber and steel creates a product that resists abrasion while absorbing impact, making them ideal for processing hard ores like granite. The panels’ aperture patterns—including continuous slots and solid designs—are optimized for specific tasks: continuous slots for dewatering, solid patterns for scalping. Their ability to reduce noise makes them suitable for operations near residential areas, ensuring compliance with noise pollution regulations. The high-temperature rubber compound option allows use in processes like coal gasification, where heat would degrade standard rubber. With a focus on customization, HUATAO can tailor these panels to meet unique mining challenges, from remote sites to high-capacity industrial plants.

Product Description

HUATAO’s rubber screen panels redefine reliability in mining, with features that address common pain points like downtime and high maintenance costs. Their anti-pegging design ensures that even sticky materials, like clay-rich iron ore, don’t clog apertures, keeping screening continuous. The panels’ thickness (30–90mm) can be chosen based on material weight, with thicker options for heavy rocks and thinner ones for fine sands. Installation is quick with snap-type fastenings, allowing a single worker to replace panels in minutes, reducing production interruptions. Suitable for temperatures up to 120°C, they perform in high-heat processes like mineral drying, expanding their utility beyond traditional screening. By combining durability with ease of use, these panels are a valuable asset for mining operations of all sizes.

Installtion Type

Square Pin Type

Snap Type

Pin Type

Tension Type

fAQ