Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

Maximizing Efficiency with Polyurethane Screen Technology

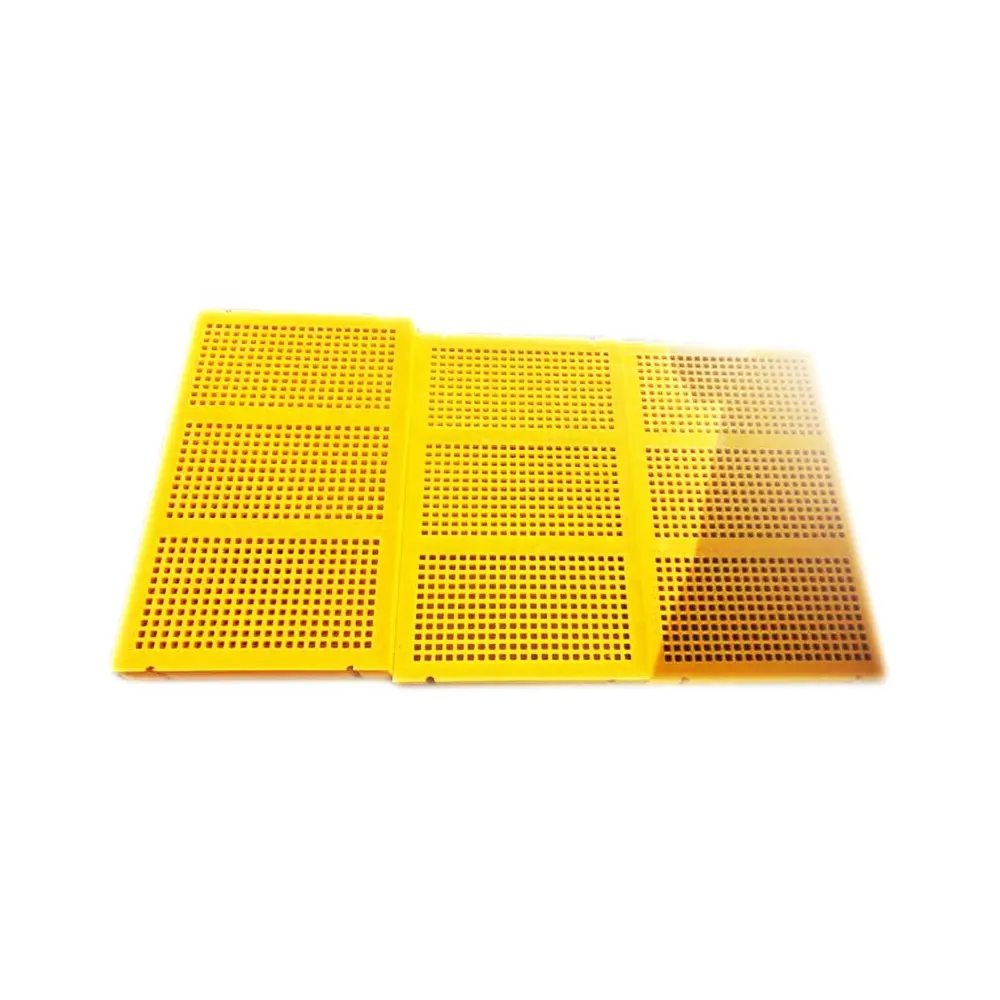

The demand for efficient material handling systems is surging as industries push for optimization. Polyurethane screens are at the forefront of this revolution, providing a solution that balances speed, durability, and environmental sustainability. Unlike traditional screens made of steel or wire, polyurethane screens are engineered to withstand harsh conditions, including high temperatures, aggressive chemicals, and continuous vibration.

By integrating polyurethane screens into industrial processes, businesses can achieve significant improvements in material flow, reduce waste, and lower operational costs. These screens are not only more efficient but also require less maintenance, making them ideal for large-scale operations. Whether youre processing raw materials, separating particles, or screening solid waste, polyurethane screens provide the precision and longevity needed to keep your operations running smoothly.

Understanding Polyurethane Screens: Material Science and Functionality

Polyurethane screens are made from a unique material known for its exceptional properties. Derived from polyols and isocyanurates, these screens are chemically resistant, flexible, and highly durable. Their construction allows them to handle a wide range of applications, from fine material screening to heavy-duty industrial processes.

One of the standout features of polyurethane screens is their high open area. This means they allow for efficient material flow while maintaining a fine mesh size, which is ideal for separating particles of varying sizes. Their lightweight construction also minimizes the strain on machinery, reducing energy consumption and extending the lifespan of equipment.

Polyurethane screens are also known for their low noise levels and resistance to corrosion, making them a superior choice for environments with harsh conditions. Additionally, their ability to handle both wet and dry materials ensures versatility across different industrial applications.

The Efficiency Edge: How Polyurethane Screens Outperform Traditional Methods

Polyurethane screens deliver unmatched efficiency compared to traditional screening solutions. Their ability to maintain performance under extreme conditions, combined with their lightweight and modular design, makes them ideal for industries where reliability and cost-effectiveness are critical.

For example, in mining operations, polyurethane screens are used to process ore with precision, ensuring that valuable minerals are separated from waste materials efficiently. In manufacturing plants, these screens are employed to size and classify raw materials, reducing waste and improving production yields.

Another key advantage of polyurethane screens is their ability to replace multiple traditional screens with a single modular panel. This not only reduces material waste but also streamlines maintenance and assembly, saving valuable downtime.

Optimizing Efficiency: Design and Application of Polyurethane Screens

The efficiency of polyurethane screens is highly dependent on their design and application. Customization plays a crucial role in maximizing their performance, as different industries require screens tailored to specific material characteristics and operational needs.

Engineers and designers work closely with manufacturers to develop screens that match the unique requirements of each project. For instance, screens can be designed with varying aperture sizes and thicknesses to handle different materials, while others can be reinforced with additional metal or rubber to enhance durability.

The use of advanced technologies in screen manufacturing ensures that polyurethane screens are not only efficient but also environmentally friendly. Many modern screens are designed with fire-resistant properties, reducing the risk of equipment failure during emergencies.

Real-World Applications of Polyurethane Screens

To illustrate the benefits of polyurethane screens, lets look at a few real-world case studies:

Mining Operations

In a mining plant, a company installed polyurethane screens to process ore more efficiently. These screens were able to handle the sticky and abrasive nature of the ore while maintaining a high open area. As a result, the plant saw a 20% reduction in operational costs due to lower wear rates and fewer screen changes.

Food Processing

A food manufacturing plant implemented polyurethane screens to separate fine particles in their production line. The screens were able to handle wet and dry materials with ease, reducing the risk of particle blocking. This led to a 15% increase in production efficiency and a significant reduction in material waste.

Recycling Plants

In a recycling plant, polyurethane screens were used to separate different types of plastics and metals. Their durability and resistance to wear made them ideal for handling abrasive materials, while their low noise levels ensured a quiet, efficient operation. This setup improved sorting accuracy by 30% and reduced energy consumption by 25%.

The Future of Polyurethane Screens: Innovation and Efficiency

As industries continue to demand higher standards of efficiency and sustainability, the potential for polyurethane screens to evolve is limitless. Upcoming advancements in screen technology may include:

- Self-cleaning capabilities that minimize maintenance and extend screen life.

- Energy-absorbing materials that reduce vibration and noise levels.

- Advanced customization options tailored to meet the unique needs of cutting-edge industries.

These innovations will further enhance the efficiency and versatility of polyurethane screens, ensuring they remain a top choice for businesses worldwide.

Maximizing Efficiency Through Polyurethane Screens

Polyurethane screens are transforming the way industries handle material screening. Their durability, efficiency, and adaptability make them a preferred choice for businesses seeking to optimize their operations. By integrating polyurethane screens into their processes, companies can achieve significant improvements in speed, cost, and energy efficiency.

As the demand for innovative solutions grows, so too will the role of polyurethane screens in driving efficiency and sustainability. Whether youre processing raw materials, separating particles, or managing waste, polyurethane screens offer a reliable and efficient solution for any industry.

Final Reflection: The Impact of Polyurethane Screens on Efficiency

The adoption of polyurethane screens is not just about improving efficiency; its about redefining the future of industrial screening. By embracing these versatile and durable screens, businesses can achieve operational excellence while reducing their environmental footprint. The future of efficiency lies in innovation, and polyurethane screens are at the forefront of this transformation.

What role will polyurethane screens play in the future of efficiency?