Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

Mold and Mildew Prevention: Why Choose Polyurethane Screens?

Imagine waking up to a musty smell in your home, only to find that mold and mildew have taken over your bathroom. It's a terrifying realization that can lead to serious health issues and property damage. But what if you could prevent them with a simple yet effective solution? Enter polyurethane screensa powerful tool in your mold and mildew prevention arsenal.

The Hidden Dangers of Mold and Mildew

Mold and mildew thrive in moist, warm environments like bathrooms, kitchens, and basements. They can cause serious health issues, such as respiratory problems, and structural damage. For example, a home in Florida required a costly $50,000 repair bill after extensive mold and mildew damage. Symptoms include respiratory issues, allergies, and asthma, making your home feel uninviting and unsafe.

Screens as a Barrier Against Mold and Mildew

Screens act as a robust barrier, preventing outdoor elements from entering your home. There are several types of screens, including:

- Metal Mesh Screens (Steel Wire): Common but less breathable.

- Fiberglass Reinforced Screens: More durable but less breathable.

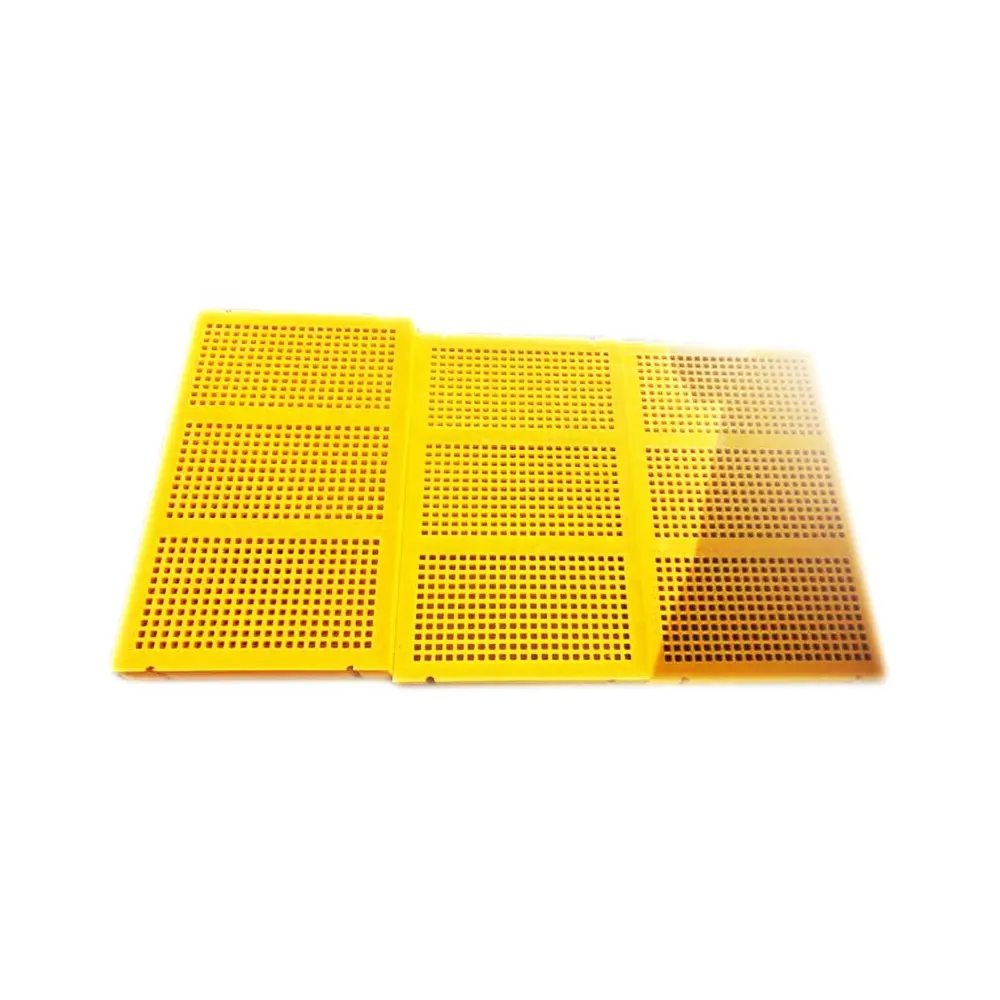

- Polyurethane Screens: Best in terms of moisture resistance, mold and mildew resistance, and UV durability.

Polyurethane screens are the ideal choice due to their excellent moisture and mold resistance.

Why Polyurethane Screens Are Better

Polyurethane screens offer exceptional durability and moisture resistance. They:

- Resist Moisture: Effective in preventing the growth of mold.

- hibit Mold Growth: Suppress mold, ensuring long-term hygiene.

- withstand UV Radiation: Remain resilient in natural conditions.

Studies have shown that polyurethane screens excel in preventing mold growth. Therefore, using polyurethane screens is highly recommended.

Practical Applications and Installation

Polyurethane screens are suitable for windows, doors, and attic ventilation openings. Proper installation is critical to prevent water leaks. Regular maintenance, such as cleaning or replacing screens, can extend their lifespan.

Detailed Application Examples

- Windows: Install on windows to prevent moisture entry.

- Doors: Install on doors to prevent mold and other contaminants.

- Attic Ventilation Openings: Install on attic vents to prevent moisture buildup.

Steps for Installation

- Clean the Installation Area: Ensure the area is free of dust and debris.

- Cut the Screen: Cut the screen to the correct size.

- Install the Screen: Secure the screen to the window frame or door frame.

- Ensure Tight Fit: Check that the screen is tight and secure to prevent water leakage.

- Regular Maintenance: Clean the screen regularly to maintain its effectiveness.

Real-World Case Study

For example, a family in their basement used polyurethane screens, successfully reducing mold growth. Before installation, the basement was often damp and moldy, causing severe air quality issues. After installing polyurethane screens, the basement's ventilation improved significantly, reducing airborne mold levels. This case study demonstrates the effectiveness of polyurethane screens in controlling mold growth.

Additional Prevention Measures

Combining polyurethane screens with other preventive measures can create a comprehensive mold and moisture control plan. Consider:

- Proper Drainage: Ensure proper roof drainage to prevent water intrusion.

- Use Dehumidifiers: Regularly use dehumidifiers to reduce indoor humidity.

- Increase Ventilation: Ensure proper ventilation in your home to prevent moisture buildup.

Conclusion

Using polyurethane screens and combining them with other preventive measures can effectively prevent mold and mildew growth. Take action now to ensure a healthier, more comfortable living environment.