Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

Leveraging Polyurethane Screen Mesh for Enhanced Industrial Filtration Solutions

In todays fast-paced industrial landscape, industries across the boardfrom mining and metallurgy to food processing and wastewater managementare increasingly seeking more efficient and reliable solutions to optimize their operations. Traditional filtration methods, though commonly used, often fall short in meeting the stringent operational and environmental demands of these industries. This has led to a growing demand for advanced filtration technologies that can handle heavy loads, resist wear and tear, and provide consistent performance. Enter polyurethane screen mesha revolutionary material that is transforming the way industries approach their filtration needs.

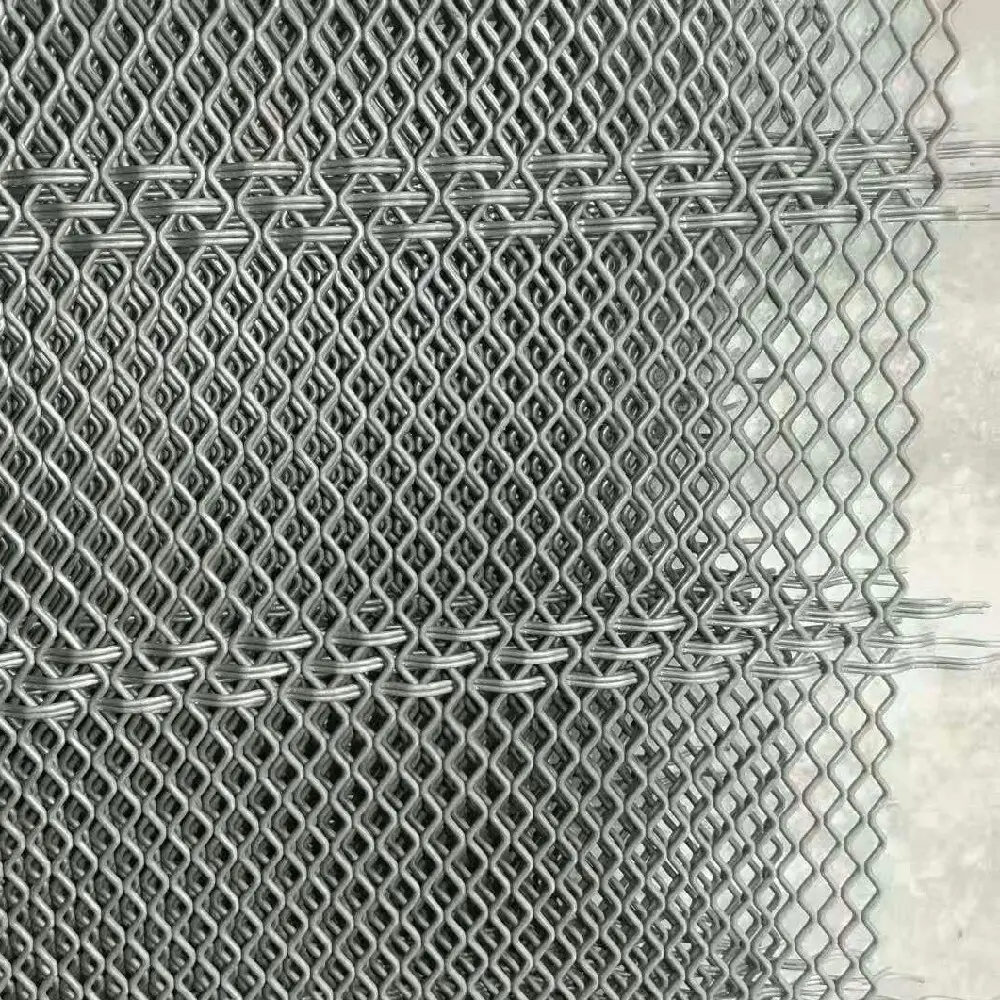

Polyurethane screen mesh is crafted from high-quality polyurethane compounds, offering a unique combination of strength and flexibility. This material is engineered to withstand the harshest of industrial environments, providing exceptional resistance to abrasion, corrosion, and chemical exposure. Unlike traditional materials such as woven wire screens, polyurethane mesh maintains its structural integrity over time, ensuring consistent performance and longevity. Its low noise levels and ease of installation further add to its appeal, making it a superior choice for modern filtration applications.

Understanding Polyurethane Screen Mesh: Composition and Benefits

Polyurethane screen mesh is a high-performance material designed for durability and flexibility. It is made from a blend of polyurethane compounds that provide a balance of strength and elasticity, ensuring it can handle heavy loads and harsh conditions without degrading. The materials resistance to wear and tear makes it more durable than traditional filters, significantly reducing the need for replacements and maintenance. This translates into lower operational costs and increased efficiency.

The benefits of polyurethane screen mesh are numerous. Its resistance to wear and tear makes it more durable than traditional materials, which often succumb to frequent wear and tear. This results in reduced downtime and maintenance costs. Additionally, the mesh's low friction coefficient and smooth surface contribute to reduced energy consumption, making it an environmentally friendly choice. Its ease of installation and low maintenance requirements further enhance its appeal, making it a highly attractive option for industries looking to streamline their filtration processes.

Case Study: Successful Implementation in Industrial Sectors

Numerous industries have already begun to harness the potential of polyurethane screen mesh. In the mining sector, companies have reported substantial improvements in both efficiency and cost-effectiveness. For example, a mining company that implemented polyurethane screen mesh in its filtration system experienced a 30% reduction in maintenance downtime and a 20% decrease in operational costs. Similarly, in wastewater treatment facilities, polyurethane mesh has proven instrumental in achieving finer filtration, leading to cleaner effluents and improved environmental compliance.

A wastewater management facility that switched to polyurethane screen mesh saw a significant improvement in water quality, meeting stricter environmental standards with ease. These case studies highlight how polyurethane screen mesh can provide substantial benefits in terms of efficiency, cost savings, and environmental compliance.

Comparative Analysis: Polyurethane Screen Mesh vs. Conventional Filters

When compared to conventional filtration materials, polyurethane screen mesh stands out for its superior performance and durability. Traditional filters, often made from woven wire or metal mesh, are prone to wear and tear, requiring frequent replacements and maintenance. In contrast, polyurethane mesh offers a much longer lifespan, reducing the need for constant upkeep. Its flexible structure and low friction coefficient further enhance its performance, allowing for smoother operation and less energy consumption.

A study conducted by a leading filtration solutions provider found that polyurethane screen mesh had a median lifespan of 5 years, compared to 2 years for traditional woven wire screens. This durability and longevity make it a cost-effective and efficient choice for industries looking to optimize their filtration processes.

Innovative Applications: Beyond Conventional Filtration

The versatility of polyurethane screen mesh extends beyond traditional filtration applications. Industries are increasingly exploring its potential in areas such as dewatering, grading, and separating. Its unique properties make it ideal for use in modular screens and trommel applications, where customized solutions are often required.

For instance, in the food processing industry, a company using polyurethane screen mesh for dewatering reported a 40% increase in throughput and a 25% reduction in energy consumption. Similarly, in the mineral processing industry, the use of polyurethane screen mesh in trommel screens led to a 20% increase in recovery rates and a 15% reduction in contamination levels.

These applications demonstrate the wide-ranging benefits of polyurethane screen mesh, making it a valuable tool for industries looking to innovate and optimize their processes.

Challenges and Considerations for Adoption

While the advantages of polyurethane screen mesh are clear, there are certain challenges to consider when transitioning to this material. The initial investment cost can be higher than traditional filters, and industry professionals must evaluate this cost-benefit ratio. Additionally, the material's compatibility with existing systems and the availability of skilled labor for installation and maintenance must be taken into account. However, the long-term benefits, including reduced maintenance and enhanced efficiency, often outweigh these initial hurdles.

A case study by a leading industrial consultancy firm found that a company that made the switch to polyurethane screen mesh experienced a 15% increase in overall efficiency and a 10% reduction in operational costs within the first year. This highlights the potential for significant cost savings and improved performance when adopting polyurethane screen mesh.

The Evolution of Filtration Technology

As technology continues to advance, the future of filtration solutions is poised for exciting developments. Polyurethane screen mesh is expected to play a central role in this evolution, with ongoing research and innovation leading to even more advanced formulations. The integration of smart technologies and automation could further enhance the capabilities of polyurethane mesh, offering unprecedented levels of precision and control.

For instance, the development of intelligent filtration systems that use real-time data to adjust filtration settings could significantly improve the efficiency and effectiveness of polyurethane screen mesh. These advancements are set to drive a new era of innovation and efficiency in industrial filtration.

Transforming Industrial Filtration with Polyurethane Screen Mesh

In conclusion, polyurethane screen mesh represents a transformative advantage for industries seeking to optimize their filtration processes. Its unique blend of durability, flexibility, and performance makes it an ideal choice for a wide range of applications. By embracing this advanced material, industries can not only improve their operational efficiency but also position themselves at the forefront of technological innovation. As the demand for high-performance filtration solutions continues to grow, polyurethane screen mesh is set to lead the way, driving a new era of innovation and efficiency in industrial filtration.