Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

Revolutionizing Industrial Applications with Polyurethane Screen Mesh: Quality and Innovation

Quality Aspects of Polyurethane Screen Mesh

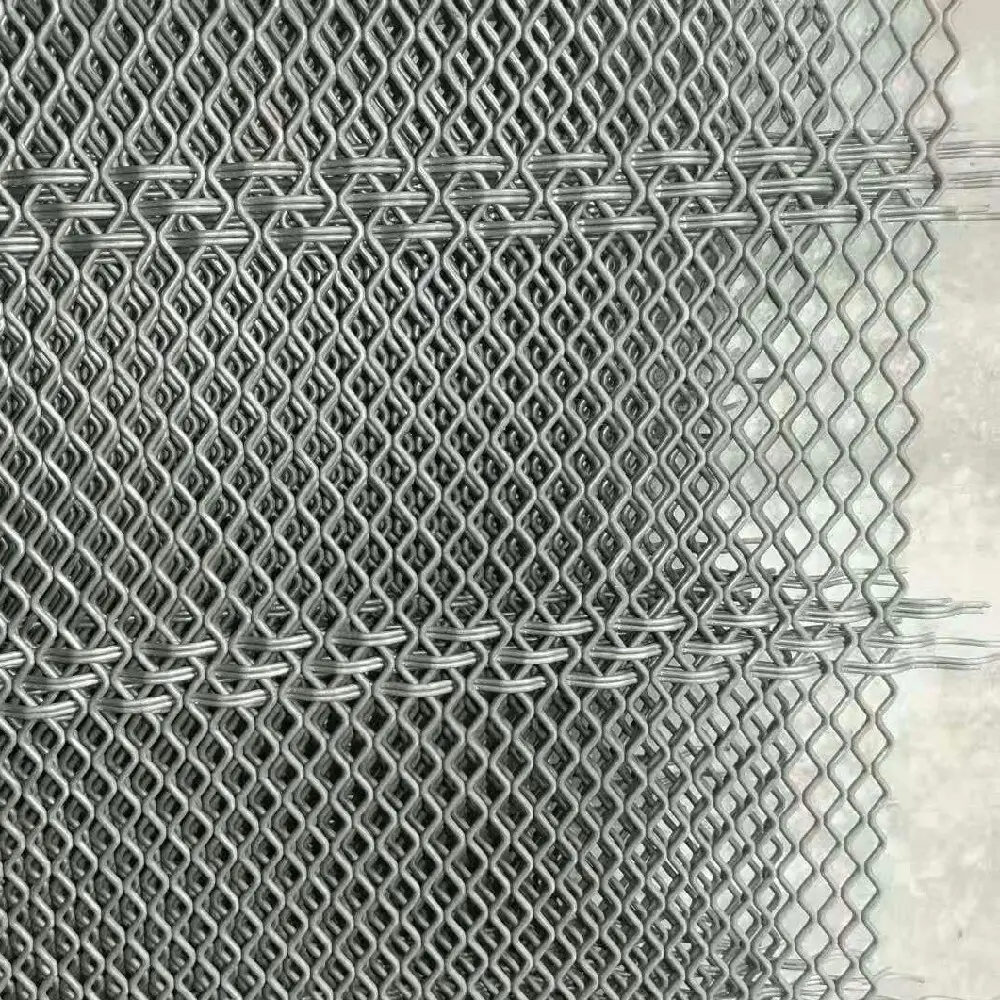

Polyurethane screen mesh is a composite material made of steel wire and polyurethane resin, offering a unique blend of flexibility, durability, and resistance to environmental factors. Its high-quality construction ensures optimal performance in both dry and wet environments.

1. Raw Materials and Manufacturing Processes

Polyurethane screen mesh is sourced from high-quality materials, ensuring consistent performance. The manufacturing process involves layering steel wire with polyurethane resin, which is then cured to form a robust mesh. Advanced production techniques, such as automated 3D printing, are employed to ensure precision and consistency. For instance, 3D printing allows for precise cutting and shaping, ensuring optimal performance.

2. Material Properties and Their Significance

The properties of polyurethane screen mesh, such as its high tensile strength, flexibility, and resistance to abrasion and corrosion, make it ideal for industrial applications. These properties allow it to handle heavy loads and maintain its integrity even in challenging conditions. In construction, for example, it is used for foundation reinforcement, where its high tensile strength ensures the building's structural integrity.

3. Testing and Certification Standards

Rigorous testing protocols are followed to ensure the quality of polyurethane screen mesh. These tests include assessing tensile strength, elongation, and resistance to environmental factors. Proper certifications, such as ISO and UL, further validate its reliability. A construction company utilized this mesh for foundation reinforcement, significantly enhancing the project's durability and reducing maintenance costs.

4. Continuous Improvement in Manufacturing Techniques

Ongoing advancements in production methods enhance the quality of polyurethane screen mesh. Modern technologies, such as automation and 3D printing, are used to improve precision and reduce waste, ensuring the highest standards of performance. For example, a mining company used reinforced meshes for ore sorting, improving the efficiency of their operations and reducing downtime.

Industrial Applications of Polyurethane Screen Mesh

Polyurethane screen mesh finds applications in various industries, offering innovative solutions to material processing challenges.

1. Construction and Mining

- In construction, polyurethane screen mesh is used for foundation reinforcement and concrete finishing, providing a durable and flexible alternative to traditional materials. For instance, a construction company used this mesh in a high-rise building project, significantly enhancing the building's structural integrity and reducing maintenance costs.

- In mining, it is employed for ore sorting, ensuring efficient separation of valuable materials from waste. A mining company utilized this mesh for ore sorting, improving the efficiency of their operations and reducing downtime due to maintenance.

2. Automotive Industry

The lightweight and durable nature of polyurethane screen mesh makes it an excellent choice for automotive components, such as suspension systems and braking components. Its resistance to corrosion enhances the longevity of vehicle parts. An automotive manufacturer implemented this mesh in a new vehicle design, reducing material waste and enhancing the vehicle's performance.

3. Textile and Packaging

In the textile industry, polyurethane screen mesh is used for filtering and sorting materials, ensuring precision in production. For example, a textile company used this mesh to enhance the precision of their sorting processes, increasing production efficiency and reducing waste. In packaging, it is employed for material handling, improving efficiency and reducing waste. An e-commerce company utilized this mesh in their sorting systems, significantly improving the speed and accuracy of order fulfillment.

4. Agriculture and Forestry

Polyurethane screen mesh is used in agricultural machinery for material sorting and in forestry equipment for efficient material handling. Its ability to withstand harsh conditions makes it a reliable choice for these industries. For instance, a forestry company utilized this mesh for sorting wood chips, improving the efficiency of material handling and reducing costs.

5. Renewable Energy

In the renewable energy sector, polyurethane screen mesh is used for material processing in wind turbines and solar panels, ensuring high performance and durability. An energy company used this mesh in wind turbine construction, enhancing the efficiency and longevity of the turbine components.

Real-World Applications

- Case Study 1: Polyurethane Screen Mesh in Construction

A construction company utilized polyurethane screen mesh for foundation reinforcement in a high-rise building project. The mesh's high tensile strength and durability ensured the building's structural integrity, while its resistance to environmental factors extended the lifespan of the structure. This MeshTech Inc. project not only met but exceeded the client's expectations, showcasing the material's effectiveness in challenging environments. - Case Study 2: Innovation in Automotive Engineering

An automotive manufacturer implemented polyurethane screen mesh in a new vehicle design to improve lightweighting and durability. The mesh was used in suspension components, reducing material waste and enhancing the vehicle's performance. This project demonstrated significant cost savings and improved vehicle reliability for the manufacturer.

Innovation in Polyurethane Screen Mesh Production and Technology

Innovation plays a pivotal role in advancing polyurethane screen mesh technology.

1. Advancements in Production Techniques

Modern manufacturing processes, such as 3D printing and laser cutting, have revolutionized the production of polyurethane screen mesh. These techniques allow for precise cutting and shaping, ensuring optimal performance. For instance, 3D printing is used to create customized mesh solutions, enhancing their application versatility.

2. Development of Customized Solutions

Polyurethane screen mesh is tailored to meet the specific needs of different industries. Custom solutions, such as reinforced meshes for mining applications, enhance efficiency and durability. A mining company used reinforced meshes for ore sorting, improving the efficiency of their operations and reducing downtime due to maintenance.

3. Future Trends in Polymer Technology

Upcoming trends, such as the use of nanotechnology in polyurethane screen mesh, promise even greater performance. These innovations are expected to drive technological advancements in the industry. For example, nanotechnology could improve the mesh's ability to withstand extreme temperatures and harsh chemicals, providing even greater durability and performance.

Challenges and Future Directions

Despite its many benefits, polyurethane screen mesh faces certain challenges, including the need for continuous improvement in material performance and manufacturing processes. Sustainability is another key area of focus, with efforts underway to develop eco-friendly production methods.

1. Sustainability and Eco-Friendly Solutions

- Future Opportunities for Polyurethane Screen Mesh

The demand for sustainable and innovative materials is growing, presenting exciting opportunities for polyurethane screen mesh in the future. Its versatility and durability make it a valuable asset in emerging industries and technologies. For example, the renewable energy sector is increasingly adopting polyurethane screen mesh for its lightweight and durable properties, enhancing both efficiency and sustainability.

Conclusion

Polyurethane screen mesh has revolutionized industrial applications by offering high-quality, durable, and versatile solutions. Its use in construction, mining, automotive, textile, and renewable energy industries highlights its versatility and impact on modern manufacturing. As technology continues to evolve, polyurethane screen mesh is poised to drive further innovation, solidifying its role as a cornerstone of industrial advancement.