Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

Custom Dewatering Screen Price List

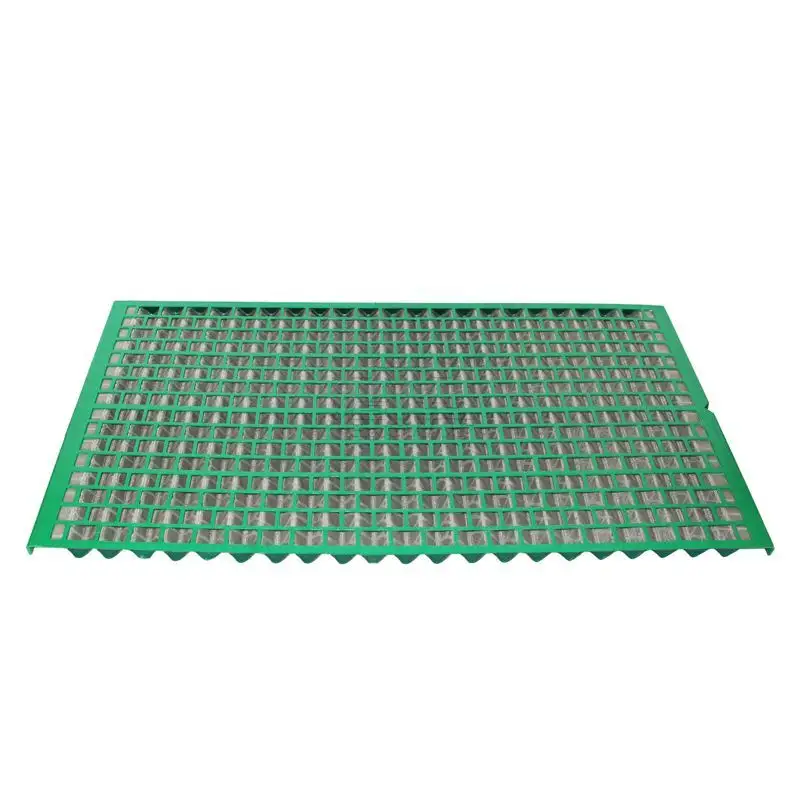

Product details of the dewatering screen

Product Description

HUATAO dewatering screen comprised of high quality is designed with a variety of styles. This product is far more preferable in terms of performance/price ratio. With advanced equipment, HUATAO LOVER LTD has strong production capacity.

Product Information

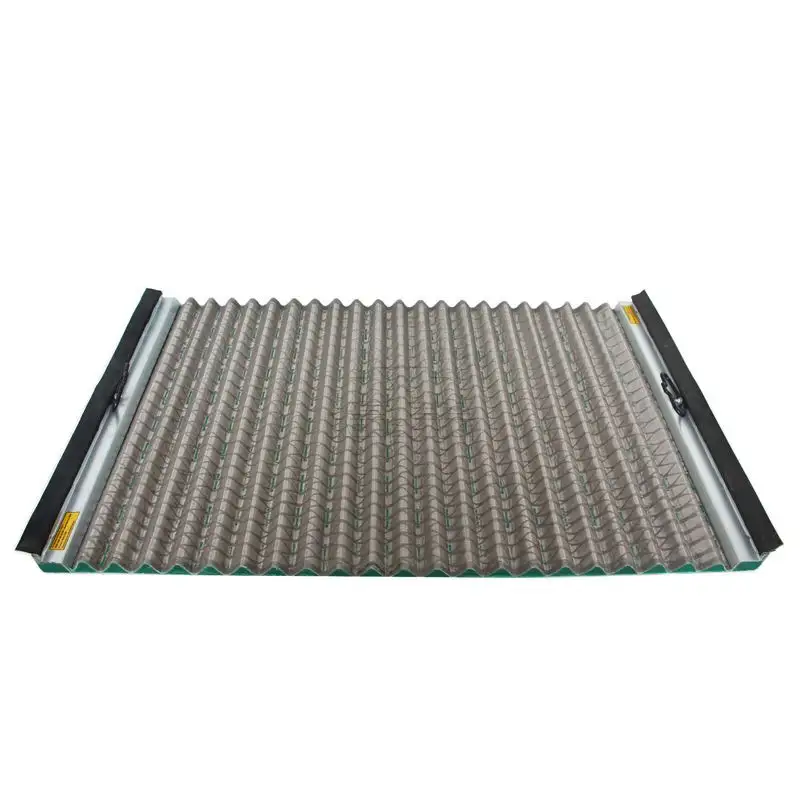

Wave screen are a type of screen used in oil and gas drilling operations to remove solid particles from drilling fluids. They are designed with a wave-like shape that allows for increased surface area and improved filtration capabilities.

The wave design also helps to reduce the amount of fluid lost during the filtration process, allowing for more efficient drilling operations. Wave screens are made from a variety of materials, including stainless steel, polyurethane, or composite materials. They are available in various mesh sizes and configurations to suit different drilling needs.

Product Feature

1. The stainless steel wire cloth combined directly bonded on the steel plank.then tightly bonded together by steel frames and metal plank.

2. Every layer of wire cloth has different meshes,accurately and reasonably making screening more micro mesh.

3. It forms a reliable whole,with high-strength steel frame,reinforced supports and moderate tension screening cloth, which greatly enhances the tolerate flow, strength and working life. Rapid wedge tensioning devices make screen installation more convenient, and save the time of machine halt for changing.

4. Wire cloth is divided into several independent small cloths to prevent excessive expansion of local damage. At the same time,with a special rubber plug to repair damage,it can save time and reduce use-cost.

Product parameters

|

Screen Model |

Range of Mesh |

Dimension(widthx Length) |

Brand & Model of Shaker |

|

HT-1(WAVE) |

20-325 |

697×1053mm |

DERRICK FLC2000 |

|

HT-2(WAVE) |

20-325 |

695×1050mm |

DERRICK FLC500 |

|

HT-3(WAVE) |

20-325 |

710×626mm |

DERRICK FLC600 |

|

HT-4(WAVE) |

20-325 |

567×1070mm |

DERRICK-HYP |

|

HT-5(WAVE) |

20-325 |

635X1253mm |

BRANDT BL-50 |

|

HT-6(WAVE) |

20-325 |

915X1150mm |

BRANDT LCM-ZD |

product display

fAQ

Company Advantage

• HUATAO, built in has been engaged in the industry for years. Under the leadership of the founder's wisdom, all the members have come all the way, and accumulated rich experience. It lays a foundation for our current achievements.

• HUATAO pays great attention to customers and advocates honesty-based cooperation. We are dedicated to providing excellent and efficient services for numerous customers.

• In recent years, HUATAO has continuously optimized the export environment and has striven to expanded export channels. Besides, we have actively opened up the foreign market to change the simplex situation of the sales market. All these contribute to the increment of market share in the international market.

• Traffic convenience including easy and open highway access and the great geographic location is conducive to the transportation of Polyweb Urethane Screens,Polyurethane Screen Panels,PU Dewatering Screen Panels,Self-cleaning Screen Mesh,Polyurethane Coated Steel Wire Rope Screen,Poly Ripple Screen,Tufflex Screen,Rubber Screen.

HUATAO's quality-reliable leatherware is produced and sold directly from the factory. Contact us for more information and we have surprises for you.