Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

For Mineral Equipment Dewatering Screen by HUATAO

Company Advantages

· The raw materials of HUATAO dewatering screen are well prepared and are efficiently used in the production.

· The product provides excellent safety and quality which have been approved by the international certifications.

· To provide the best service, HUATAO's staff has been working hard.

Product Information

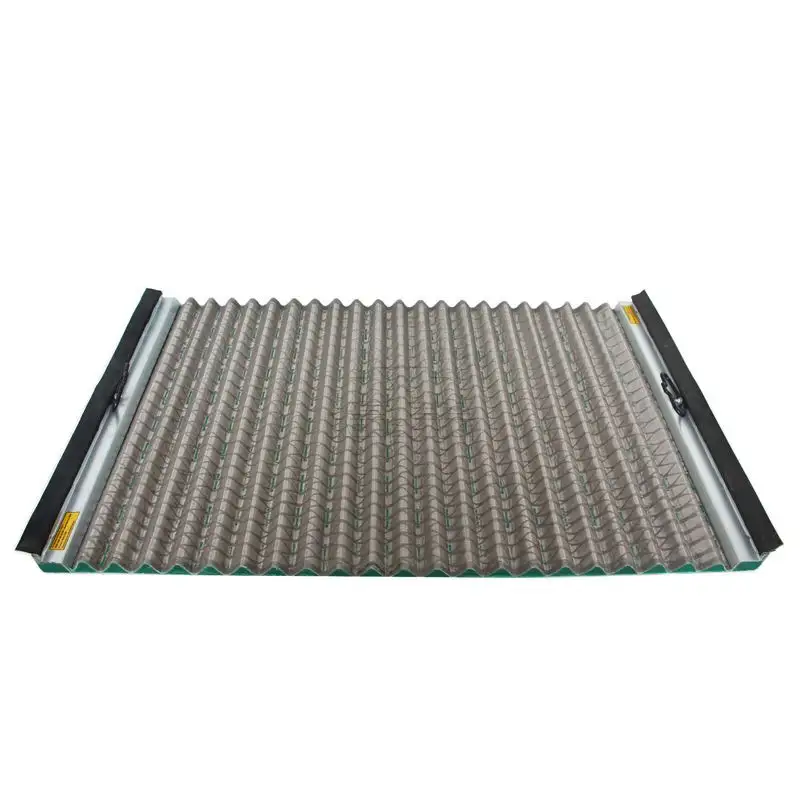

Wave screen are a type of screen used in oil and gas drilling operations to remove solid particles from drilling fluids. They are designed with a wave-like shape that allows for increased surface area and improved filtration capabilities.

The wave design also helps to reduce the amount of fluid lost during the filtration process, allowing for more efficient drilling operations. Wave screens are made from a variety of materials, including stainless steel, polyurethane, or composite materials. They are available in various mesh sizes and configurations to suit different drilling needs.

Product Feature

1. The stainless steel wire cloth combined directly bonded on the steel plank.then tightly bonded together by steel frames and metal plank.

2. Every layer of wire cloth has different meshes,accurately and reasonably making screening more micro mesh.

3. It forms a reliable whole,with high-strength steel frame,reinforced supports and moderate tension screening cloth, which greatly enhances the tolerate flow, strength and working life. Rapid wedge tensioning devices make screen installation more convenient, and save the time of machine halt for changing.

4. Wire cloth is divided into several independent small cloths to prevent excessive expansion of local damage. At the same time,with a special rubber plug to repair damage,it can save time and reduce use-cost.

Product parameters

|

Screen Model |

Range of Mesh |

Dimension(widthx Length) |

Brand & Model of Shaker |

|

HT-1(WAVE) |

20-325 |

697×1053mm |

DERRICK FLC2000 |

|

HT-2(WAVE) |

20-325 |

695×1050mm |

DERRICK FLC500 |

|

HT-3(WAVE) |

20-325 |

710×626mm |

DERRICK FLC600 |

|

HT-4(WAVE) |

20-325 |

567×1070mm |

DERRICK-HYP |

|

HT-5(WAVE) |

20-325 |

635X1253mm |

BRANDT BL-50 |

|

HT-6(WAVE) |

20-325 |

915X1150mm |

BRANDT LCM-ZD |

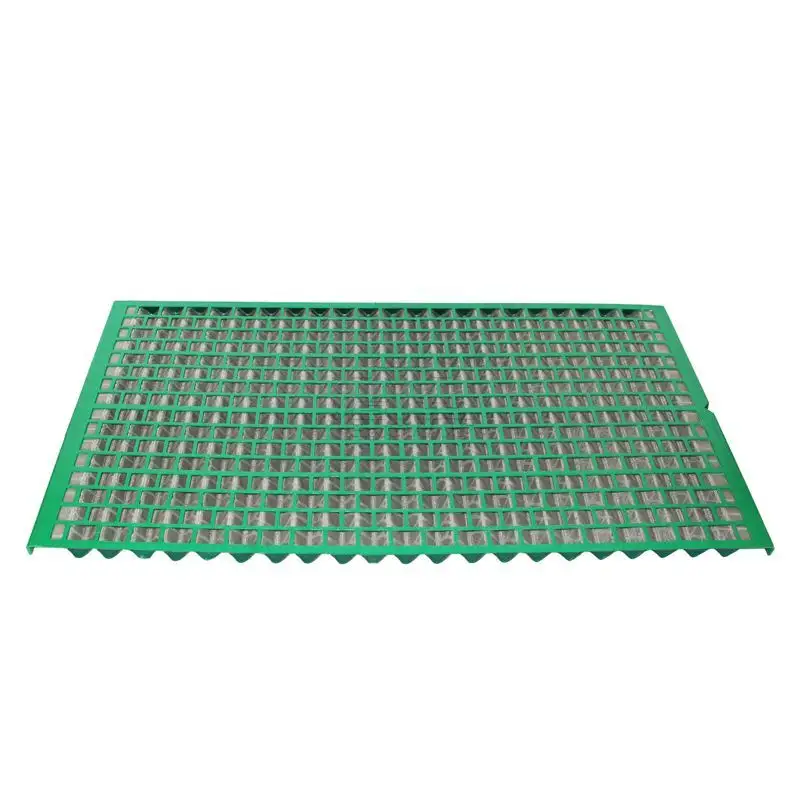

product display

fAQ

Company Features

· HUATAO brand is famous in the field of dewatering screen.

· Our factory is well-equipped. We have advanced machines and experienced staff. This versatile combination of man and machinery means our production is calibrated, recalibrated and fine-tuned to meet specific requests. Our factory is well-equipped. It has a broad range of state-of-the-art machinery which are run by experienced, skilled workers and fed by a reliable raw material supply chain that is as tested and proven as our product. We have a well equipped factory. Some of the machines are imported from Japan and Germany. They help the company to create original designs and do high-volume production on tight deadlines.

· HUATAO LOVER LTD will strive to strengthen quality management and improve business efficiency. Get info!

Product Comparison

Compared with similar products, our dewatering screen's outstanding advantages are as follows.