Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

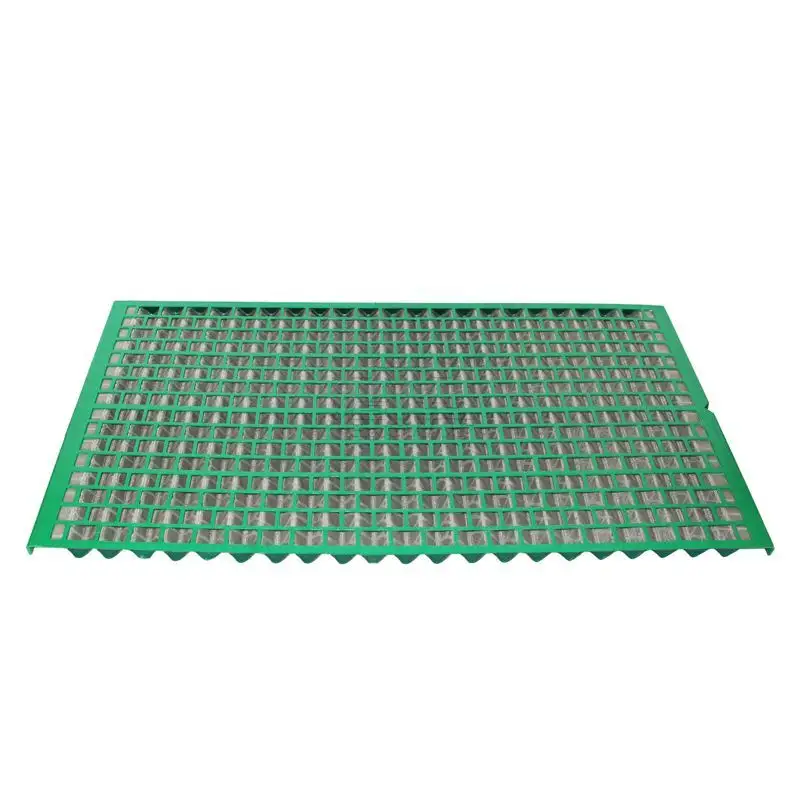

HUATAO Shaker Screen Mesh Made in China

Product details of the shaker screen mesh

Product Information

Through our innovative use of the latest technology, the manufacturing process of the HUATAO shaker screen mesh is optimized. The quality of this product is in compliance with international standards. The customers of HUATAO will continue to enjoy the same service standards and warranties of shaker screen mesh.

Product Information

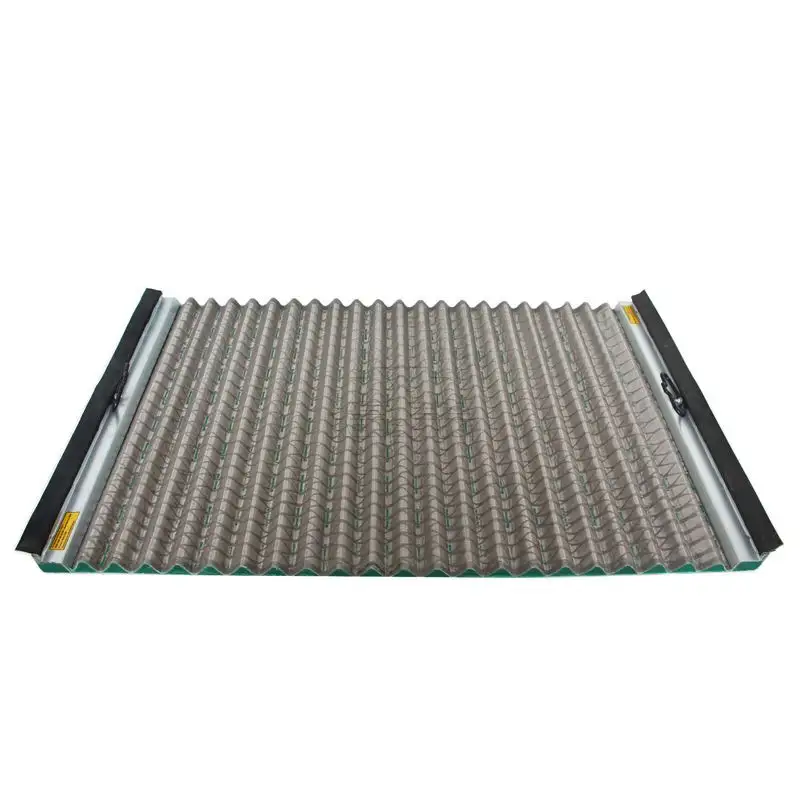

Wave screen are a type of screen used in oil and gas drilling operations to remove solid particles from drilling fluids. They are designed with a wave-like shape that allows for increased surface area and improved filtration capabilities.

The wave design also helps to reduce the amount of fluid lost during the filtration process, allowing for more efficient drilling operations. Wave screens are made from a variety of materials, including stainless steel, polyurethane, or composite materials. They are available in various mesh sizes and configurations to suit different drilling needs.

Product Feature

1. The stainless steel wire cloth combined directly bonded on the steel plank.then tightly bonded together by steel frames and metal plank.

2. Every layer of wire cloth has different meshes,accurately and reasonably making screening more micro mesh.

3. It forms a reliable whole,with high-strength steel frame,reinforced supports and moderate tension screening cloth, which greatly enhances the tolerate flow, strength and working life. Rapid wedge tensioning devices make screen installation more convenient, and save the time of machine halt for changing.

4. Wire cloth is divided into several independent small cloths to prevent excessive expansion of local damage. At the same time,with a special rubber plug to repair damage,it can save time and reduce use-cost.

Product parameters

|

Screen Model |

Range of Mesh |

Dimension(widthx Length) |

Brand & Model of Shaker |

|

HT-1(WAVE) |

20-325 |

697×1053mm |

DERRICK FLC2000 |

|

HT-2(WAVE) |

20-325 |

695×1050mm |

DERRICK FLC500 |

|

HT-3(WAVE) |

20-325 |

710×626mm |

DERRICK FLC600 |

|

HT-4(WAVE) |

20-325 |

567×1070mm |

DERRICK-HYP |

|

HT-5(WAVE) |

20-325 |

635X1253mm |

BRANDT BL-50 |

|

HT-6(WAVE) |

20-325 |

915X1150mm |

BRANDT LCM-ZD |

product display

fAQ

Company Feature

• HUATAO receives wide recognition and enjoys a good reputation in the industry based on pragmatic style, sincere attitude, and innovative methods.

• Founded in HUATAO has a history of years. We have accumulated rich industry experience relying on the wisdom and skills of all members.

• HUATAO has advantageous conditions for product delivery. Nearby there is a prosperous market, developed communication, and traffic convenience.

• HUATAO's products are mainly exported to Europe, America, Asia and Africa and other countries and regions.

HUATAO is greatly motivated by your inquiries and suggestions!