Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

Poly Screen Panels - for Mining Industry - HUATAO

Product Information

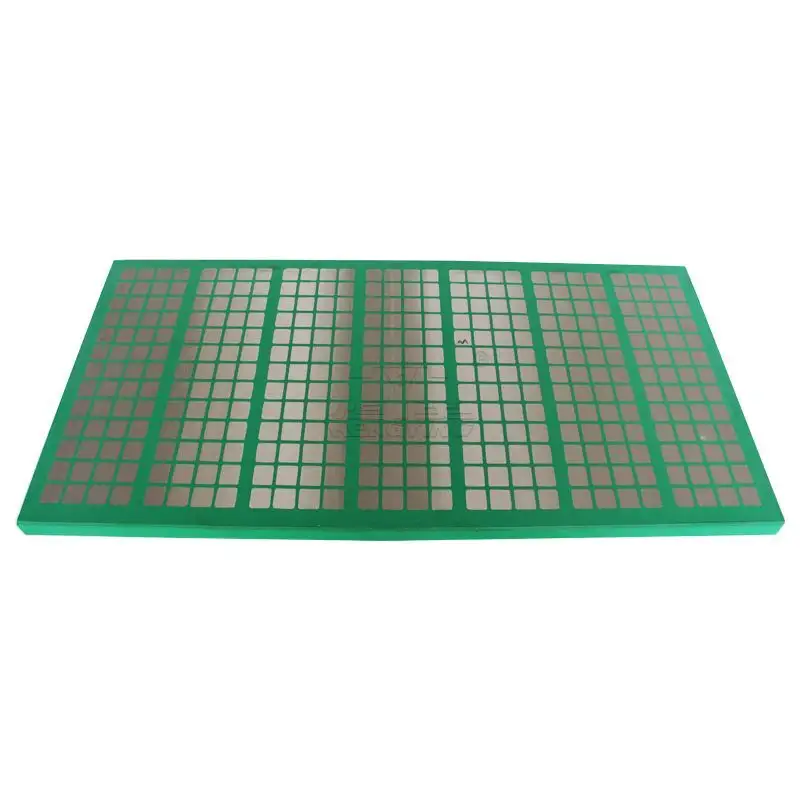

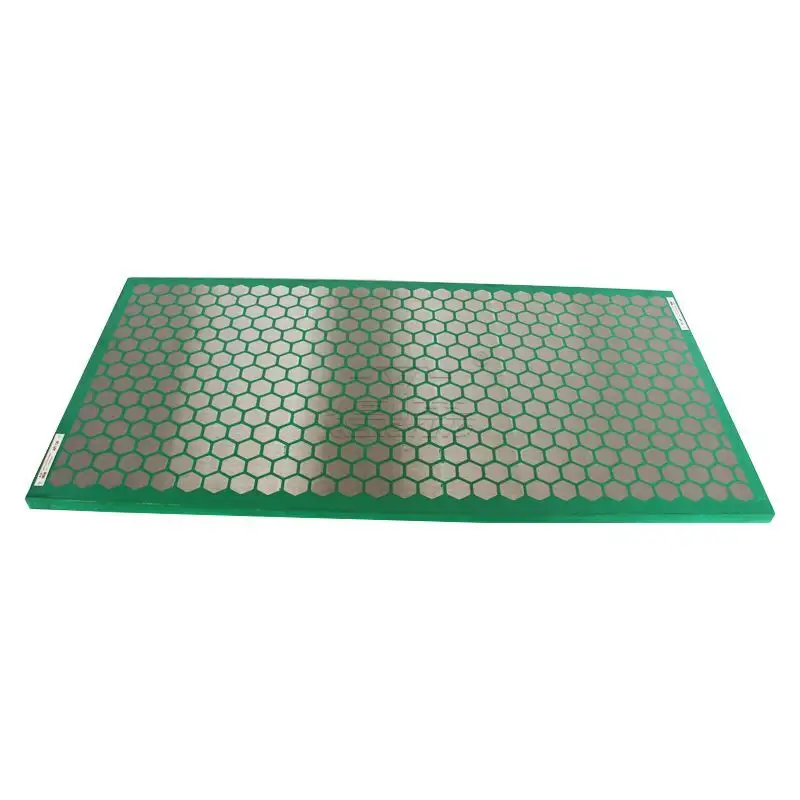

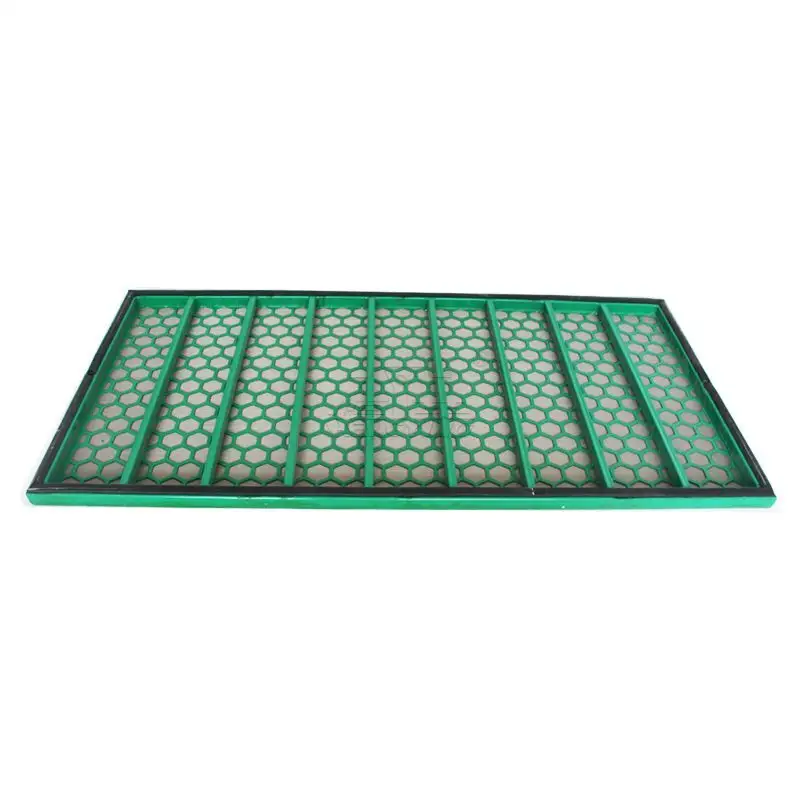

Steel frame screen are a type of shaker screen that feature a steel frame around the mesh or screen. The frame provides additional support and stability to the screen, making it more durable and resistant to damage or warping. Steel frame screens are commonly used in drilling operations where the drilling fluid contains heavier or larger solid particles that require a stronger and more robust screen to remove them.

They are also often used in high-volume drilling operations where frequent screen replacement is needed, as they can be quickly and easily replaced without requiring extensive downtime. Steel frame screens are available in a variety of mesh sizes and configurations to suit different drilling requirements.

Product Feature

1. The stainless steel wire cloth combined directly bonded on the steel plank.then tightly bonded together by steel frames and metal plank.

2. Every layer of wire cloth has different meshes,accurately and reasonably making screening more micro mesh.

3. It forms a reliable whole,with high-strength steel frame,reinforced supports and moderate tension screening cloth,which greatly enhances the tolerate flow,strength and working life .Rapid wedge tensioning devices make screen installation more convenient, and save the time of machine halt for changing .

4. Wire cloth is divided into several independent small cloths to prevent excessive expansion of local damage.At the same time,with a special rubber plug to repair damage,it can save time and reduce use-cost.

Product parameters

|

Screen Model |

Range of Mesh |

Dimension (width x Length) |

Brand & Model of Shaker |

|

HT-1 |

20-325 |

585×1165mm |

MON |

|

HT-2 |

20-325 |

635×1253mm |

KING COBRA&COBRA |

|

HT-3 |

20-325 |

913×650mm |

VSM300 |

|

HT-4 |

20-325 |

720×1220mm |

KTL48 SERIES |

|

HT-5 |

20-325 |

712×1180mm |

D380 |

|

HT-6 |

20-325 |

737*1067mm |

FSI 50&500&5000 |

product display

fAQ

Company Advantages

· HUATAO poly screen panels is made by our skilled professionals who have been specialized in this industry for years.

· The superior quality of the product guarantees service life.

· HUATAO LOVER LTD will maintain the efficient operation of the organization and management system under normal conditions.

Company Features

· HUATAO LOVER LTD is a reliable company based in China. We have been skilled in poly screen panels designing and manufacturing since established.

· We have state-of-the-art machines that can produce a broad spectrum of products in a highly economical way. With superb processing quality, they help us achieve consistently high-quality and impressive turnaround times.

· We will seize any possible opportunity to improve and optimize our service for poly screen panels. Get info!

Application of the Product

poly screen panels of HUATAO is widely used and has a wide range of applications.

With rich manufacturing experience and strong production capability, HUATAO is able to provide professional solutions according to customers' actual needs.