Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

Innovative Uses of Polyurethane Screen in Everyday Life

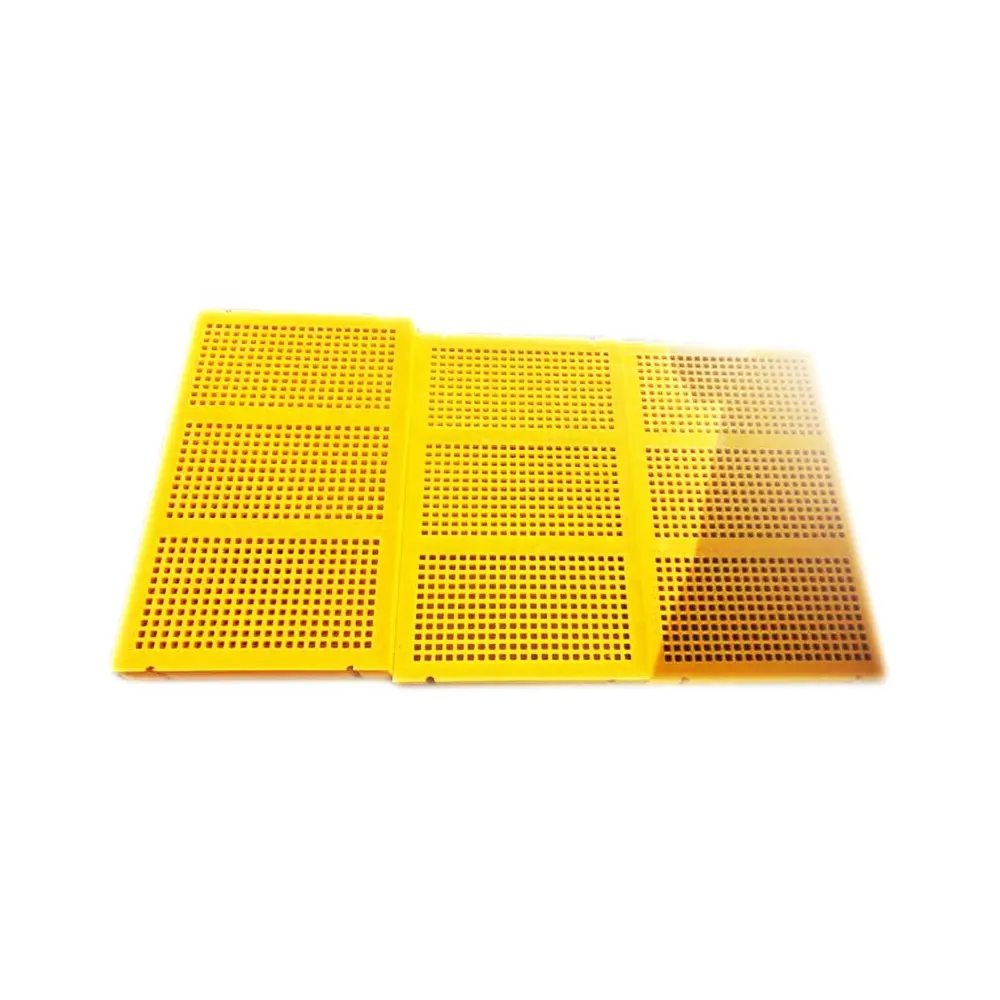

Polyurethane screens are unsung heroes in our daily lives, working behind the scenes to make our gadgets, homes, and environments safer and more functional. Without them, many of the advancements we enjoy today would simply not be possible. Let's dive into the surprising ubiquity and versatile applications of polyurethane screens.

The Hidden Strength Behind Smart Gadgets

Ever washed your smartphone and noticed that it remained unscathed? This is often thanks to the polyurethane screens inside. Known for their remarkable durability, these screens protect our devices from scratches, impacts, and even liquids. Their lightweight nature ensures a sleek and modern design, while their sensitivity allows for seamless touch interactions. Polyurethane screens are not just components; they are essential in ensuring our gadgets remain dependable and user-friendly.

Shaping the Future of Home Improvements

In the world of home improvement, polyurethane screens are quiet revolutionaries. They offer a unique blend of durability, affordability, and aesthetic appeal, making them perfect for modern living. Whether you're looking to renovate your home office or create a cozy living room, these screens can enhance both functionality and style. Their resistance to wear and tear makes them ideal for high-traffic areas, ensuring longevity and ease of maintenance.

Protecting Our Environment with Polyurethane Screens

In an era where sustainability is paramount, polyurethane screens play a vital role in environmental conservation. Their use in water filtration systems is particularly noteworthy. These screens efficiently remove impurities, contributing to cleaner water supplies and helping reduce environmental impact. Additionally, in waste management, polyurethane screens aid in the separation and processing of materials, promoting recycling efforts and minimizing landfill waste. This dual benefit of cleaning water and processing waste makes polyurethane screens a crucial tool in our quest for sustainability.

Health and Safety: A Vital Role

Polyurethane screens are not just impressive in the tech and home improvement sectors; they are essential in health and safety settings. In medical devices, these screens ensure sterile and precise filtration, ensuring patient safety and care. For instance, in dialysis machines, polyurethane screens prevent the introduction of contaminants, thus protecting patients from infections. Similarly, in safety gear, these screens provide robust protection without compromising comfort. Whether it's helmets, masks, or other protective equipment, polyurethane screens offer a balance of performance and user-friendliness.

Art and Design: A Creative Fusion

Art and design have also found a special place for polyurethane screens. Their flexibility and adaptability allow artists to explore innovative expressions. Screens can be used as canvases or structural elements, offering new possibilities for visual storytelling and interactive experiences. Consider an installation that combines digital projections with physical screens, creating an immersive and engaging environment. This fusion of technology and art not only enhances the aesthetic appeal of works but also introduces a layer of interactivity, making art more engaging and accessible.

Future Prospects: Emerging Technologies

As technology continues to evolve, polyurethane screens are set to become even more versatile. With the rise of smart homes and the Internet of Things (IoT), these screens are poised to play an increasingly significant role. From interactive displays and advanced filtration systems to other smart devices, the potential applications are vast. Imagine a home where every device is connected and optimized for efficiency and comfort, all thanks to the innovation of polyurethane screens.

A Comprehensive Overview

Polyurethane screens have proven to be more than just functional components; they are catalysts for innovation across various fields. As we continue to explore their diverse applications, it's clear that they hold immense potential to transform everyday life in remarkable ways. Whether you're redesigning your home, using the latest gadgets, or contributing to environmental and health sustainability, polyurethane screens offer a world of possibilities.

Additional Suggestions for Enhancing the Article:

- Introduction and Engagement:

- Add a surprising fact or a hook to capture attention. For example, Did you know that the same material used in your smartphone's screen can help clean water in developing countries? This would make the opening more engaging.

- Transitions:

- Use more dynamic linking words or phrases to create a smoother flow. For example, instead of Furthermore, you might use Additionally, Moreover, or In addition to to connect ideas more effectively.

- Niche Applications:

- Delve deeper into niche areas. For instance, explore how polyurethane screens are used in medical devices, or how they contribute to the functionality of smart home gadgets. This would provide more depth and make the article more comprehensive.

- Conciseness:

- Ensure conciseness by rephrasing or removing redundant information. This will make the article more reader-friendly and easier to follow.

- Visuals and Imagery:

- Add a few well-chosen visuals or diagrams to enhance the reader's understanding and engagement. For example, include images of polyurethane screens in action or diagrams of how they are used in different applications.

- Audience Tailoring:

- Tailor the article to a specific audience. For example, if your target readers are more tech-savvy, focus on the applications of polyurethane screens in gadgets and technology. If your readers are more environmentally conscious, emphasize the role of polyurethane screens in sustainability.

With these adjustments, the article will be even more engaging and impactful.