Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

The Future of Dewatering in Agriculture: Innovations Powering Growth

The Vital Role of Dewatering in Agriculture

In the vast landscape of modern agriculture, water management is a cornerstone of sustainable practices. Dewatering, the process of removing excess water from soil and crops, plays a crucial role in preventing waterlogging and ensuring optimal growth. This essential process is vital for maintaining soil health and crop productivity. Imagine a scene where drenched soil, unable to absorb water, leads to inefficiencies in irrigation. This is where dewatering screens come into play, offering a reliable solution to this challenge.

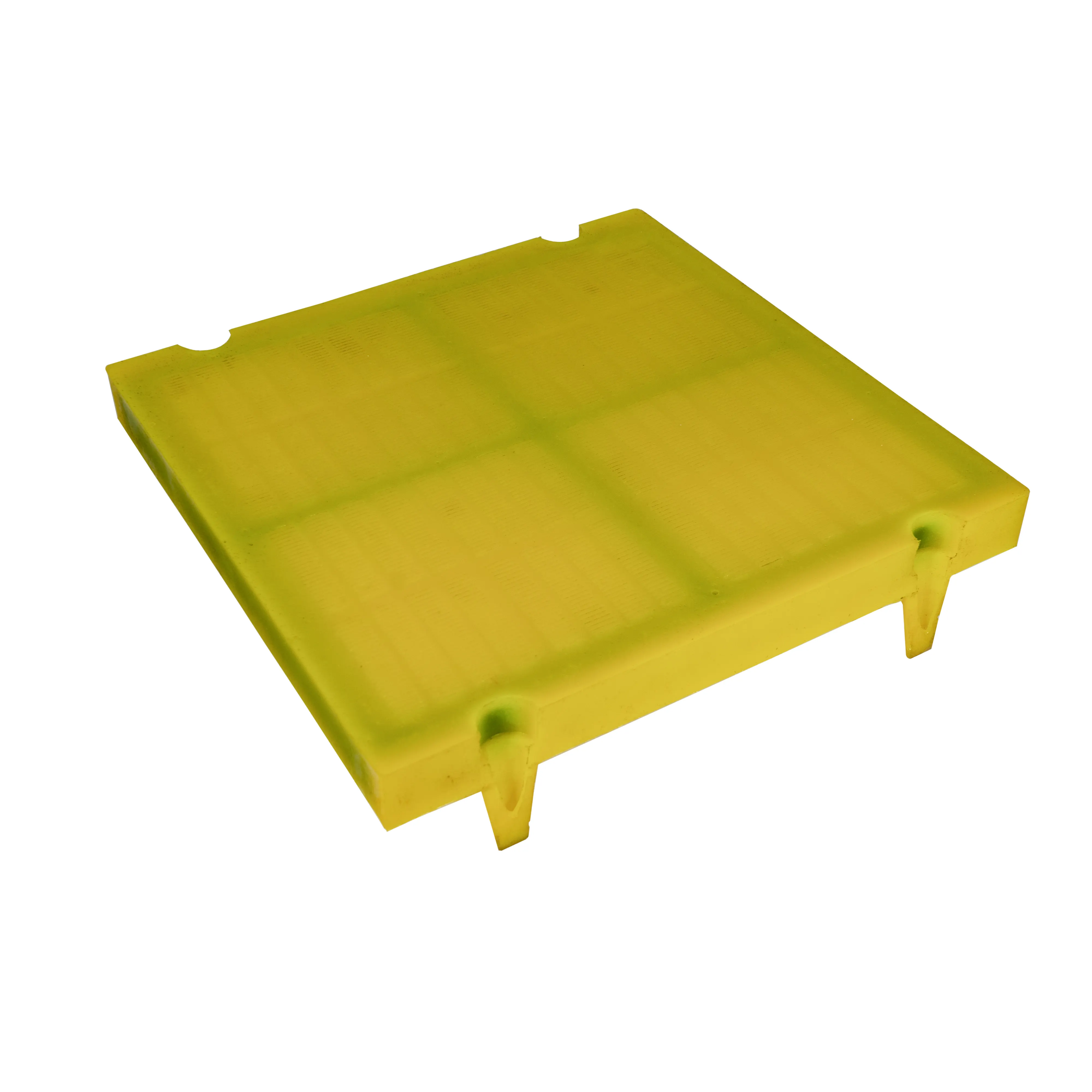

Dewatering screens, a key innovation in agriculture, are designed to filter out excess water, preventing it from infiltrating the soil and causing issues like root rot and reduced yields. These screens are not just simple tools; they are integral to maintaining a balanced water system, crucial for a global population dependent on arable land. As we delve into the future of dewatering, it becomes clear that these technologies are not only essential but also pivotal in addressing the challenges of climate change and resource scarcity.

Understanding Dewatering Screens in Agriculture

Dewatering screens are mechanical devices designed to capture and retain water, ensuring it does not infiltrate the soil. They operate by creating a barrier between the soil and water, thereby preventing waterlogging. These screens come in various forms, each tailored to specific agricultural needs. Whether used in vineyards, rice paddies, or cornfields, dewatering screens are adaptable, ensuring consistent water management across diverse farming environments.

The efficiency of dewatering screens lies in their ability to filter water at high rates, often surpassing natural infiltration processes. This capability not only saves water but also reduces the strain on irrigation systems. In regions where water is a scarce resource, such as the Horn of Africa, dewatering screens have become a lifeline, enabling farmers to cultivate essential crops despite adverse climatic conditions.

Innovations in Dewatering Technology

The future of dewatering technology is marked by continuous innovation, with advancements transforming traditional methods into cutting-edge solutions. Smart dewatering systems, equipped with automated controls, offer a significant leap forward. These systems can monitor soil moisture levels in real-time, adjusting water application rates to optimize crop growth and water conservation.

AI-driven dewatering systems take this a step further, using machine learning to predict trends and adjust operations accordingly. Such technologies not only enhance efficiency but also reduce the risk of water overuse, a critical concern in data-scarce regions. Beyond automation, sustainable dewatering practices, such as bio-based filters, are emerging, reducing the environmental footprint of these technologies.

Sustainability is no longer an afterthought but a core component of dewatering solutions. Energy-efficient dewatering screens and systems are designed to minimize their ecological impact, ensuring compatibility with global sustainability goals. These innovations are paving the way for a future where dewatering is both efficient and environmentally responsible.

Case Studies: Successful Implementation of Dewatering Screens

Successful implementations of dewatering screens are abundant, with examples ranging from developing countries to agricultural-rich regions. In the Philippines, farmers who installed dewatering screens in their rice paddies reported a 20% increase in yield, demonstrating the tangible benefits of these technologies. Similarly, in the Indo-Gangetic Plain of India, dewatering screens have replaced traditional water management methods, enhancing crop yields and reducing soil degradation.

A notable case study involves a Ugandan research station that tested AI-driven dewatering systems. The results were impressive, with a 30% reduction in water loss and a 15% increase in crop health. These examples illustrate how dewatering innovations can transform agricultural practices, yielding higher returns and environmental benefits.

Comparative Analysis of Traditional vs. Modern Dewatering Methods

Traditional dewatering methods, such as manual drainage and open furrows, have their place but are increasingly being replaced by more efficient technologies. Manual systems, while simple, are labor-intensive and often result in significant water loss. In contrast, modern dewatering screens offer a higher filtration rate, reducing water waste and conserving resources.

Modern methods also differ in their environmental impact. Traditional systems often lead to soil erosion and water pollution, whereas advanced dewatering technologies are designed to minimize these effects. For instance, bio-based filters reduce the emission of greenhouse gases, contributing to a more sustainable agricultural landscape.

The choice between traditional and modern methods often depends on specific conditions. In regions with limited technology access, traditional methods may still be preferred. However, as technology advances and resources become more accessible, modern solutions are becoming the norm, driving global agricultural efficiency and sustainability.

Future Trends and Predictions in Dewatering Technology

Looking ahead, the future of dewatering technology is poised for significant transformation. AI-driven systems are expected to become more prevalent, offering real-time data analysis and adaptive control. These systems will not only enhance efficiency but also enable farmers to respond to changing climatic conditions, such as shifting monsoon patterns.

Sustainable dewatering practices will continue to evolve, with a growing emphasis on reducing energy consumption and minimizing environmental impact. Innovations in material science could lead to the development of more durable and cost-effective screens, expanding their applicability globally.

As climate change exacerbates water stress, the demand for innovative dewatering solutions will surge. Collaboration between agricultural professionals, engineers, and technologists will be crucial in developing solutions that address both immediate and long-term challenges.

Harnessing the Power of Dewatering Screens for Agricultural Growth

Dewatering screens are not just tools for managing water; they are catalysts for agricultural growth, sustainability, and food security. By harnessing the power of these technologies, farmers can optimize water use, enhance crop yields, and mitigate environmental damage. The future of dewatering lies in a combination of innovation, sustainability, and smart solutions, ensuring that agriculture remains a vital force in a changing world.

As we move toward a more sustainable future, the role of dewatering screens will continue to expand. Innovations in technology, coupled with a growing awareness of environmental and economic challenges, will drive the adoption of these tools worldwide. It is an exciting era for agriculture, where dewatering screens are leading the charge toward a more efficient, sustainable, and productive farming system.