Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

The Ultimate Dewatering Screen Setup for Optimal Performance

Dewatering screens play a crucial role in a wide array of industrial processes, from wastewater treatment to construction site sediment removal. These versatile equipment help optimize the efficiency of handling and processing materials by removing excess water and ensuring consistent product quality.

Introduction to Dewatering Screens

Dewatering screens, also known as Dewatering Vibrating Screens, are highly efficient classifiers used in a variety of applications. They are designed to separate solid particles from liquids, facilitating the dewatering process and improving overall material handling efficiency. Common applications include dewatering, desliming, rinsing, sizing, washing, degritting, and more. These screens are especially useful in industries dealing with sand, gravel, coal, crushed aggregates, mineral sand, iron ore, precious and semi-precious metals, frac sand, and other granular materials.

Key Factors Affecting Dewatering Screen Performance

To achieve the best performance from dewatering screens, several factors must be carefully considered:

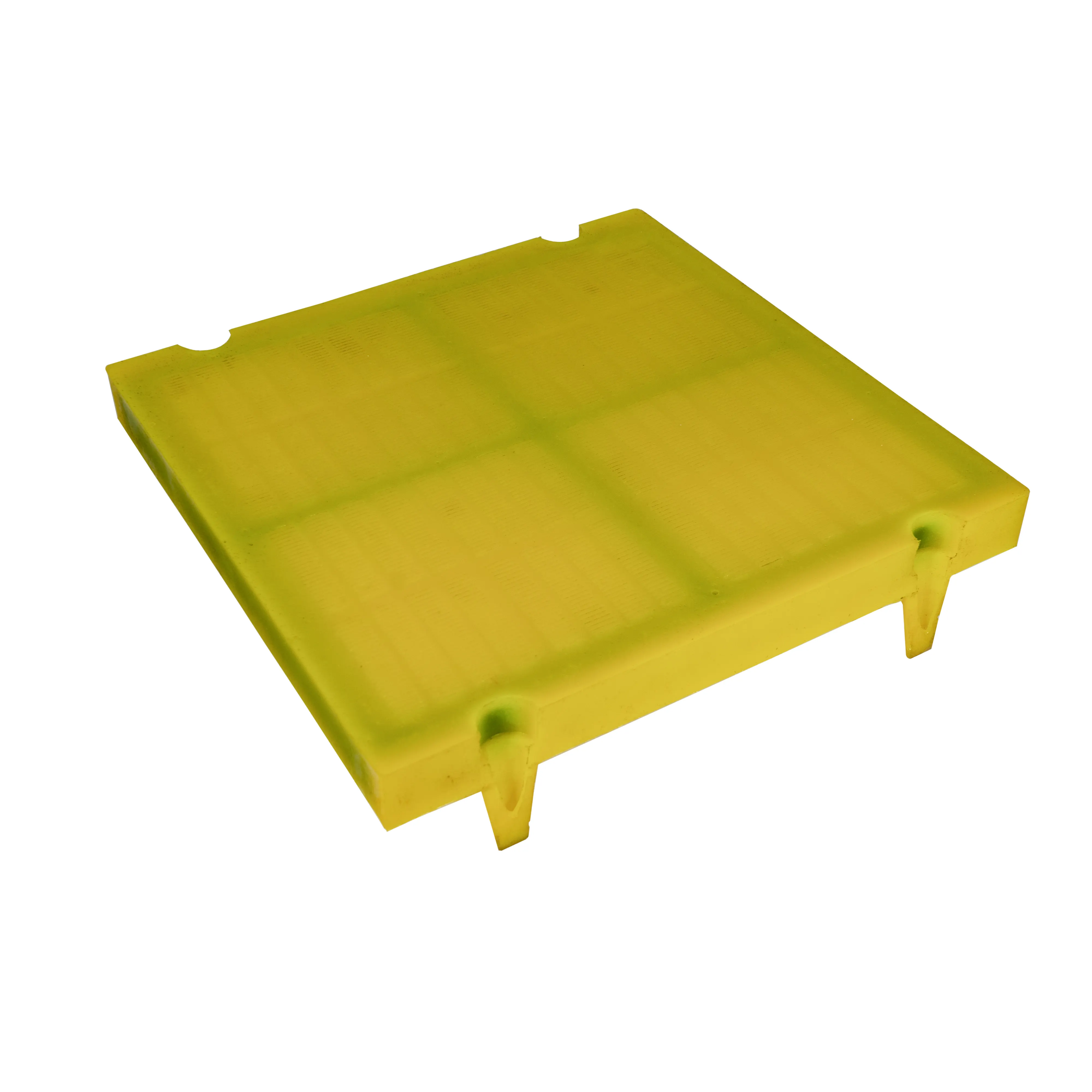

1. Mesh Density and Material: The choice of mesh density and material is critical. Higher mesh density can lead to finer particle separation but may reduce throughput. Materials like polyurethane offer high impact resistance, low temperature resistance, and wear resistance, making them an excellent choice for challenging applications.

2. Vibration Frequency and Amplitude: The frequency and amplitude of the vibrations influence the efficiency of the dewatering process. Higher frequencies can enhance the separation of finer particles, while appropriate amplitudes ensure proper fluidization of materials without causing excessive wear on the screen.

3. Feed Rate and Particle Size Distribution: The feed rate and the size distribution of particles being processed affect the screen's performance. Consistent feed rates and particle sizes help maintain optimal separation and minimize the risk of blockages.

Enhancing Dewatering Efficiency Through Design

Design elements significantly impact the efficiency and longevity of dewatering screens:

1. Optimizing Screen Deck Configuration: The configuration of the screen deck is crucial for effective dewatering. Proper hole sizes and spacing can ensure efficient removal of water without compromising the integrity of the material.

2. Frame Rigidity and Stability: A robust frame ensures that the screen operates at optimal levels without deformation. Strong frames also help distribute vibration evenly, reducing the likelihood of screen damage.

3. Importance of Proper Weir Design: The weir design is vital for directing the flow of water and ensuring that the material is evenly distributed across the screen. An effective weir helps prevent clogging and maintains consistent performance.

Practical Considerations for Installation and Operation

Proper installation and regular maintenance are essential for ensuring the longevity and efficiency of dewatering screens:

1. Best Practices for Installation: Careful installation is critical. Proper alignment and securing of the screens ensures optimal performance and reduces the risk of accidents. It is also important to consider the foundation and support system to handle the vibration and impact loads.

2. Regular Maintenance and Troubleshooting Tips: Routine inspections and maintenance can prevent unexpected downtime. Regular cleaning and replacement of worn-out components, such as the screen media, are essential.

3. Impact of Environmental Factors: Environmental conditions can significantly affect screen performance. Protecting the screens from extreme temperatures, excessive moisture, and other environmental stresses can help maintain their effectiveness.

Comparative Analysis: Screen Types and Their Suitability

When choosing a dewatering screen, it is crucial to consider the specific requirements of your application. Heres a comparison of traditional and advanced dewatering screens:

- Traditional Dewatering Screens: These are effective for general applications but may lack the advanced features and durability of modern screens. They are often simpler in design and may require more frequent maintenance.

- Advanced Dewatering Screens (e.g., DOVE and NESAN D Series): These screens offer superior performance, including higher efficiency, longer lifespan, and better resistance to wear and tear. Models like DOVE Dewatering Screens and NESAN D Series Dewatering Screens are equipped with advanced features such as better vibration control, modular screen decks, and energy-efficient designs.

Successful Dewatering Screen Implementations

To illustrate the effectiveness of different dewatering screens, consider the following case studies:

1. Example 1: Industrial Wastewater Treatment Plant

A wastewater treatment plant implemented the NESAN D Series Dewatering Screens to optimize the dewatering process. The screens efficiently removed excess water from sludge, leading to significant reductions in energy consumption and operational costs.

2. Example 2: Construction Site Sediment Removal

At a construction site, the DOVE Dewatering Screens were used to remove sediment from excavated materials. The screens robust design and high efficiency ensured that the site remained operational with minimal downtime, meeting the stringent requirements for sediment removal.

Future Trends in Dewatering Screen Technology

As technologies advance, dewatering screens are becoming more sustainable and energy-efficient:

1. Emerging Technologies: New materials and designs are continually being developed to improve the performance and durability of dewatering screens. These advancements include thinner and more flexible screen panels, enhanced vibration control systems, and intelligent monitoring and control systems.

2. Sustainability and Energy Efficiency: There is a growing emphasis on reducing the environmental impact of dewatering screens. Manufacturers are focusing on designing screens that are more energy-efficient and easier to recycle, contributing to a circular economy.