Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

Understanding the Role of Dewatering Screens in Industrial Processing: Essential Insights

In todays fast-paced manufacturing world, efficiency and sustainability are paramount. Dewatering screens are essential tools for ensuring optimal moisture control, transforming industries by reducing water usage and enhancing product quality. These screens are not just pieces of equipmentthey are a cornerstone of modern industrial efficiency.

What is a Dewatering Screen? A Technical Overview

Dewatering screens are specialized pieces of equipment designed to remove excess water from materials, leaving them in a drip-free state. Constructed from robust materials such as stainless steel, these screens feature a vibrating mechanism that facilitates the separation of water from solid particles. The screen vibrates, moving material across the surface and separating water from solids. Think of it like a clothes dryer, where wet clothes are shaken to remove excess moisture.

Applications of Dewatering Screens Across Industries

Dewatering screens are versatile and indispensable across a variety of industries. Here are some key applications:

- Mining: Dewatering screens are used to process minerals and ores, ensuring that excess moisture is efficiently removed to improve downstream processing.

- Wastewater Treatment: These screens are employed to separate solid waste from water, contributing to more effective recycling processes.

- Sand and Gravel: Dewatering screens play a crucial role in producing clean, dry aggregates for construction purposes.

- Food Industry: Dewatering screens are used to remove excess moisture from food products, ensuring that they are more consistent and easier to handle.

- Textiles: In textile processing, dewatering screens help in achieving higher yield by removing excess water from fabrics and yarns.

Comparative Analysis: Dewatering Screens vs. Traditional Methods

When compared to traditional dewatering techniques, such as sedimentation tanks or screw washers, dewatering screens offer distinct advantages. They provide a more compact solution with a smaller footprint, and their ability to achieve lower moisture contentdown to as low as 7%is unmatched. For instance, studies have shown that dewatering screens can reduce water content by up to 7% compared to traditional methods, significantly saving energy and resources.

Innovative Designs and Technological Advancements in Dewatering Screens

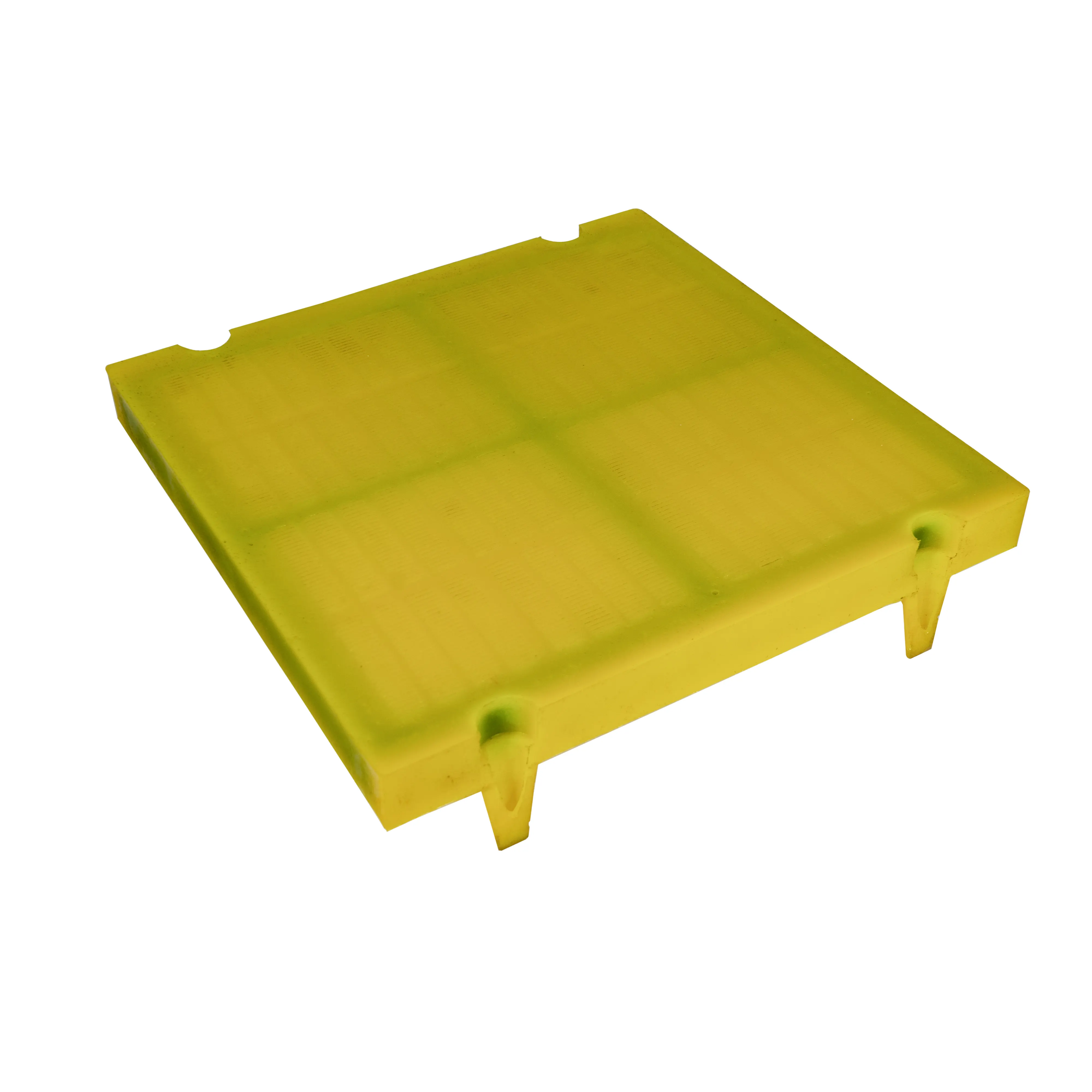

Recent years have seen significant innovations in dewatering screen design. Modular screen decks now allow for customization according to specific applications, while advancements in vibration technology have improved the efficiency of water removal. High-performance materials and anti-corrosive coatings extend the lifespan of these screens, making them more sustainable and cost-effective in the long run.

For example, a new model of dewatering screen features a variable vibration frequency that adapts to different materials, ensuring optimal performance and energy efficiency. These advancements not only improve the dewatering process but also reduce maintenance costs and extend the screen's life.

Challenges and Considerations in Implementing Dewatering Screens

Integrating dewatering screens into existing industrial processes can present challenges. Ensuring the correct setup and maintenance is crucial to avoid excessive wear and prolong the equipment's life. Key considerations include selecting the appropriate screen aperture size and adjusting vibration parameters to match material properties. Regular maintenance and monitoring are essential to optimize performance and prevent downtime.

For example, improper installation can lead to uneven vibrations, which can cause the screen to wear out faster. Regularly checking and adjusting the screen settings can help maintain optimal performance and extend the life of the equipment. Proper training for maintenance personnel can also prevent common pitfalls and ensure smooth operation.

The Evolving Role of Dewatering Screens in Industry

Looking ahead, the role of dewatering screens is set to evolve alongside advancements in technology and environmental considerations. The push towards more sustainable industrial practices will drive innovations aimed at reducing energy consumption and enhancing water recycling capabilities. As industries continue to prioritize efficiency and sustainability, dewatering screens will play a pivotal role in shaping the future of industrial processing.

For instance, with the rise of renewable energy and sustainable practices, dewatering screens will increasingly integrate with solar and wind power systems to further reduce energy consumption. Additionally, advancements in recycling technologies will allow for the reuse of dewatered water, reducing overall water usage in industrial processes.

The Impact of Dewatering Screens on Industrial Efficiency

In conclusion, dewatering screens are vital for modern industrial efficiency. By removing water quickly and effectively, they help industries save energy, reduce waste, and produce cleaner, higher-quality materials. Their role in industrial processes is not just about moisture controlits about driving sustainability and efficiency across a wide range of industries.

As technology continues to advance, the potential for dewatering screens to revolutionize industrial processing becomes increasingly evident, solidifying their status as a cornerstone of modern industry.