Huatao Group-Vibrating Screen Technology Solution and Service for Quarry & Mining Industry Since 2008.

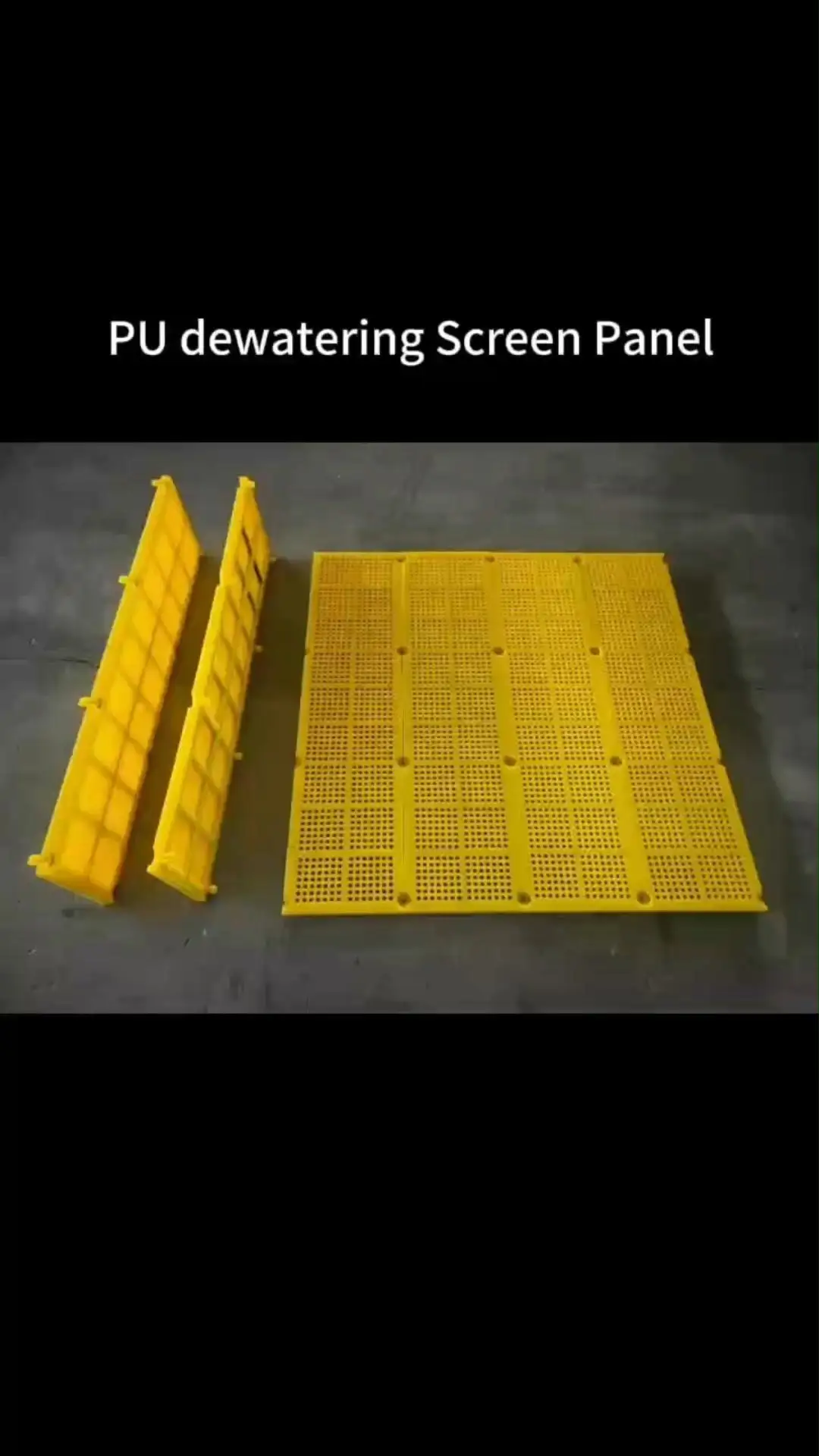

Polyurethane Dewatering Screen Panel 40mm Thickness with Steel Frame 0.15mm Slot for Sand washing plant

Material: steel frame and polyurethane surface.

Thickness: 30mm, 45mm, 50mm.

Opening size: Width: 0.1mm - 2.5mm , Length: 4mm - 16mm.

Screen width: 305mm, 500mm and 515mm.

Screen length: 305mm, 610mm, 650mm, 915mm,1200mm and 1220mm.

Connection type: Bolts, Rose nail, Trim strip , Rail support. WS85 can be designed

Package: Carton Box or Wooden Box

Payment Terms: T/T, Paypal.

Shipping Options: FedEx, DHL, UPS, Air Freight, Sea Freight, Train, Truck

Terms: EXW, FOB, CIF, DDU, DDP

Product Information

For efficient dewatering in mining and construction, polyurethane dewatering screen panels—steel-framed with a polyurethane surface—deliver durability. The steel frame ensures high tensile strength, while the polyurethane layer resists abrasion, lasting 3–8 times longer than metal screens.

These panels are available in 30mm, 45mm, and 50mm thicknesses, with slot openings (0.1–2.5mm width; 4–16mm length) for precise water separation from fine materials like coal. Screen dimensions (widths 305mm, 500mm, 515mm; lengths 305mm to 1220mm) fit most vibrating screens, ensuring easy integration.

Connection options—rose nails, trim strips—simplify installation. Their anti-blinding design prevents clogging, maintaining performance, while low noise and lightweight properties improve workplace conditions. Beyond dewatering, they assist in classification, serving sand processing effectively.

Product Features

● Wear and abrasion resistance.

● High efficiency.

● High tensile strength. Steel frame added to strengthen the tensile strength.

● Lightweight and easy to install.

● Various connection types to fit different machines.

● Non-blinding.

● Low noise.

● Long service life.

Application

Polyurethane dewatering screen panel can provide a ramp which helps to maximize screen washing capabilities and mainly used for dewatering and dehydration for various materials. Such as below: Tailing. Coal. Gravel. Sand.

product display

fAQ